Nozzle Installation & Operation - Roadside/Right-of-Way Applications

- The supply line from the pump should be one pipe size larger than the nozzle thread size. For example, if the nozzle has a 1/2” thread, the supply line should be 3/4”.

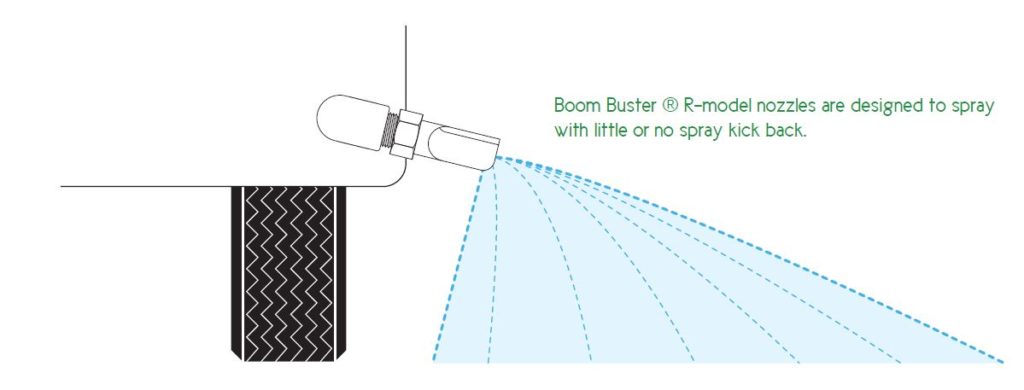

- Boom Buster® nozzles are tested at a height of 48” above ground level. They can be mounted lower or higher than 48”. This may require adjusting the angle of the nozzle to achieve the correct distance (in feet) as specified in the nozzle selection guide.

- Some Boom Buster® nozzles are designed to be mounted level, while others should be angled either up or down.

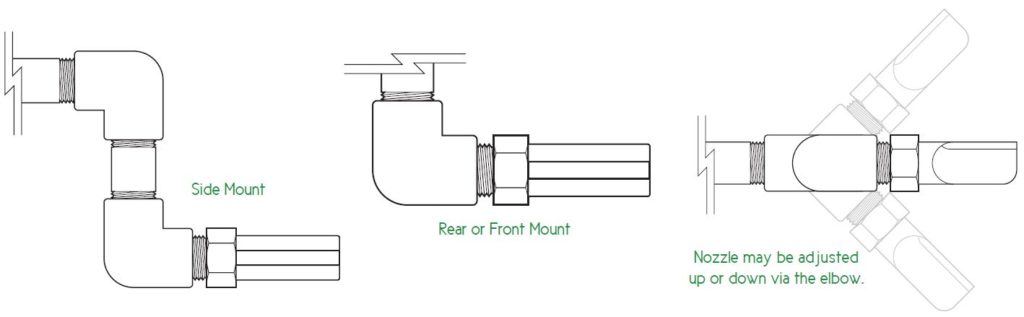

- Mounting nozzles on street elbows allows for quick and easy nozzle adjustment. Example mounting options and adjustments are illustrated below.

- In some applications, except for the small nozzles, these nozzles may be operated at speeds up to thirty

- miles per hour.

- While small mesh nozzle strainers are not necessary, a coarse mesh inline strainer may be necessary if tank or water supply becomes contaminated with large particles.

- Minimize drift by spraying just above the ground to be sprayed. As with any method of spraying, high or gusty wind can cause some pattern shifting. Always use good judgment when spraying; do not spray in high winds.

- Spray it safe! Always wear protective clothing and handle all chemicals with care.

Boom Buster® nozzles have been tested and classified in accordance with ASABE S-5721. Certification for all nozzles is available upon request.